Bronze Guide Blocks for Industrial Automation Systems

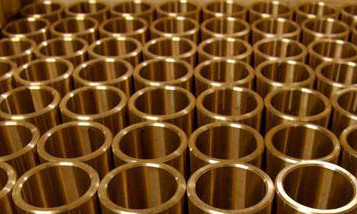

When you think of a bronze bearing we normally envision a cylindrical shaped object in our head. While that assumption is true for a large percentage of the bronze bearings we manufacture, there are bronze bearings that don’t resemble that image at all.

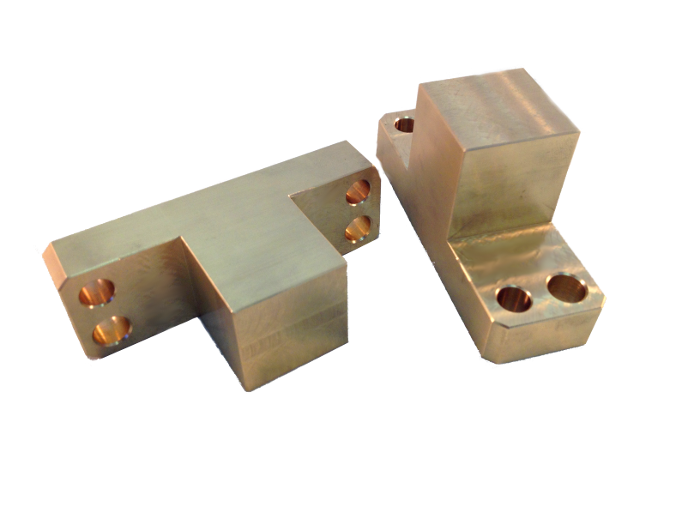

These bearings tend to be called names like guide blocks, wear plates, and liners. They vary in size and shape but generally all of them utilizing milling machining versus turning machining used in the manufacture of the bronze sleeve bushing type products. These bronze bearings utilize the various properties of the bronze alloys much like their round counterparts do. Generally used in applications where metal will be rubbing against metal. By using a bronze guide block or liner the bronze acts as a sacrificial part while at the same time giving higher wear properties to the assembly. With proper lubrication these parts can provide performance for great ranges of operation time. The difference that the wear plates, liners, and blocks have is the surface and method of which the load will be born upon. This factor should be taken into consideration when designing these types of parts.

We recently had the pleasure to manufacture a number of these type of bronze bearings for a prestigious automation system manufacturer. These parts are used as guide block and stop blocks. For this project we utilized an advanced milling machining center. This state of the art CNC Machine guarantees a end product with tight tolerances free from defects.

These part were all machined from C93200 SAE 660 Bearing Bronze alloy. The addition of a small percentage of lead gives this bearing bronze alloy its superior bearing properties. The lead does not alloy into the alloy matrix like the Copper, Tin, and Zinc. Instead it forms small pools amongst the grain structure. These pools of lead serve a dual purpose of enhanced machinability and a form of natural internal lubrication in case of the event of dry start. While the lead does enhance properties of C93200 this alloy is not considered self-lubricating. That means a method of supplying additional lubrication to parts like these must be designed and used.

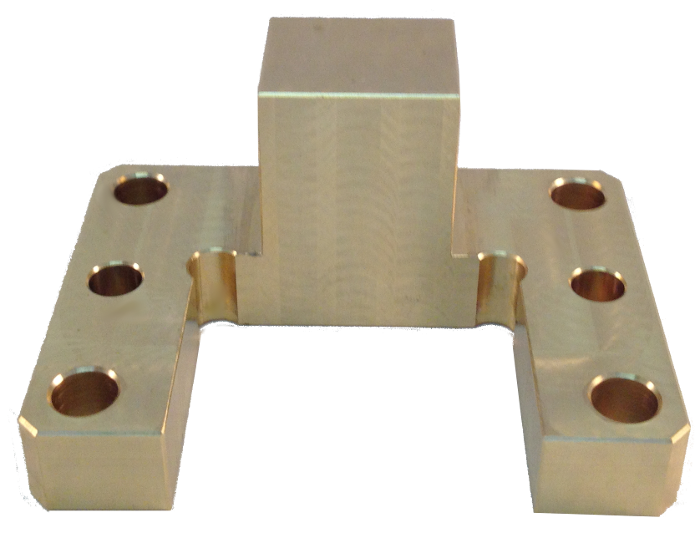

If your application does not allow for external lubrication, you still have options. We will machine your part out of the C93200 SAE 660 material and mill and plug the bearing with solid lubricant inserts. These inserts are graphite based and provide the self-lubrication needed for a number of critical applications. The graphite acts as a film that covers the bearing surface, much in the same way that graphite will cover your fingers if you rub a pencil over them. These solid lubricant plugs are a great option for applications with higher temperatures where standard lubricants would burn away.

For further information on the various bronze bearing products manufactured by National Bronze Mfg., follow the links below. Use the contact for to have a sales engineer go over your specific project to see how National Bronze Mfg. can manufacture solutions for you.

Graphite Plugged Bronze Bearings