Nickel Aluminum Bronze Corrosion Resistance

What is corrosion?

Corrosion is the deterioration of metal as the result of chemical reactions and its surrounding environment. Corrosion can have a variety of negative effects on metal. Ultimately corrosion of a metal component can lead to the failure of the component to function. There are a number of different types of corrosion in metals. They include:

- Galvanic corrosion

- Stress-corrosion cracking

- Erosion corrosion

- Cavitation corrosion

- Selective corrosion

Nickel Aluminum Bronze Alloys are known their superior corrosion resistance in seawater and many other chemical environments. The corrosion resistant property relies on the formation of a copper/aluminum oxide film. This film is self-repairing in media containing even low levels of oxygen.

This oxide film provides the following benefits:

- It adheres firmly to the surface of the substrate

- It has a resistance to liquid penetration

- The hardness of the alumina content creates higher resistance to erosion and abrasion

Nickel Aluminum Bronze alloys can be considered for service in the following chemicals. Selection must take into account the operational temperature, concentrations, service conditions, and impurities.

| Acetic Acid | Carbon Dioxide | Glycerine | Sewage |

| Acetic Anhydride | Carbonic Acid | Glycerol | Soaps |

| Acetate Solvents | Caustic Potash | Hydrochloric Acid | Sodium Bisulfate |

| Alcohols | Caustic Soda | Hydrofluoric Acid | Sodium Bisulfite |

| Aldehydes | Chlorine (dry) | Hydrogen | Sodium Chloride |

| Aluminum Chloride | Chloroform | Inert Gases | Sodium Hypochlorite |

| Aluminum Fluoride | Citric Acid | Lactic Acid | Sodium Nitrate |

| Aluminum Hydroxide | Coal Tar | Linseed Oil | Sodium Silicate |

| Aluminum Sulfate | Coal Tar Solvents | Magnesium Chloride | Sodium Sulfate |

| Ammonia (Dry) | Copper Sulfate | Mineral Oils | Sodium Bisulfite |

| Amyl Chloride | Dyestuffs, Acid Dyes | Naphthenic Acids | Sulphur |

| Asphalt | Esters | Nickel Sulfate | Sulfuric Acid |

| Barium Chloride | Ethers | Nitrogen | Sulfurous Acid |

| Benzole | Fats | Oxalic Acid | Sulfur Dioxide |

| Borax | Fatty Acids | Oxygen | Tannic Acid |

| Boric Acid | Fluosilicic Acid | Oleic Palmytic Stearic Acid | Tartaric Acid |

| Brine | Formaldehyde | Paints | Trichlorethylene |

| Bromine (Dry) | Formic Acid | Petroleum Products | Tri-Sodium Phosphate |

| Calcium Chloride | Furfural | Phosphoric Acid | Zinc Chloride |

| Calcium Hypochlorite | Fuel Gases | Pickling Solutions | Zinc Sulfate |

| Cane Sugar Liquors | Gelatine | Refrigeration Gases | |

| Carbolic Acid | Glucose | Seawater |

Applications that utilized Nickel Aluminum Bronze Corrosion Resistance

Paper Making

Nickel Aluminum Bronze is used in the paper making industry, where it comes into contact with low concentrations of hypochlorites and bisulfites found in the pulp. It has excellent corrosion resistance under these conditions and is used for beater bars, valves and suction rolls.

Glass Industry

Nickel Aluminum Bronze is used in the glass industry in the frosting of glass, utilizing its corrosion resistance in hydrofluoric acid. In this industry hydrofluoric acid is sprayed through nickel aluminum bronze nozzles onto light bulbs.

Aerospace

Nickel Aluminum Bronze alloys C63000 AMS 4640, C95510 AMS 4880, C63020 AMS 4590, and C95520 AMS 4881 are used in landing gear bushings. The excellent bearing properties combined with the corrosion resistance in salt conditions during deicing of run ways in the winter make these alloys ideal for this application

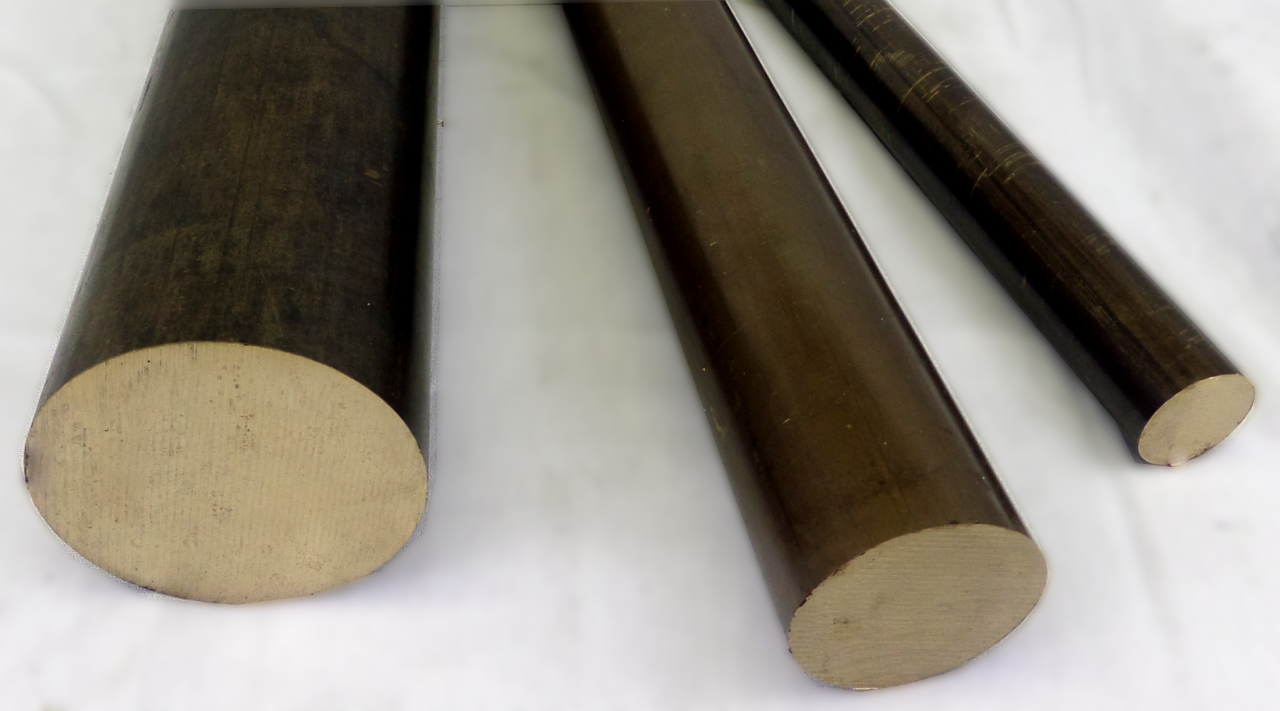

Nickel Aluminum Bronze Alloys

Here at National Bronze Mfg. Co., we offer the following Nickel Aluminum Bronze Alloys in both bar stock form and full machined components:

C63000 AMS 4640 Nickel Aluminum Bronze

C95510 AMS 4880 Nickel Aluminum Bronze

C63020 AMS 4590 Nickel Aluminum Bronze

C95520 AMS 4881 Nickel Aluminum Bronzes