Design Guidelines for Powdered Metal Bearings

Economics usually require large quantities to justify cost of equipment and special tooling. Minimum quantities of 3,000 units are suggested.

PM is unique in its capability to fabricate parts with a controlled level of porosity. Porosities up to 50% are possible

PM can be used to make parts out of unusual metals and alloys – materials that would be difficult if not impossible to produce by other means.

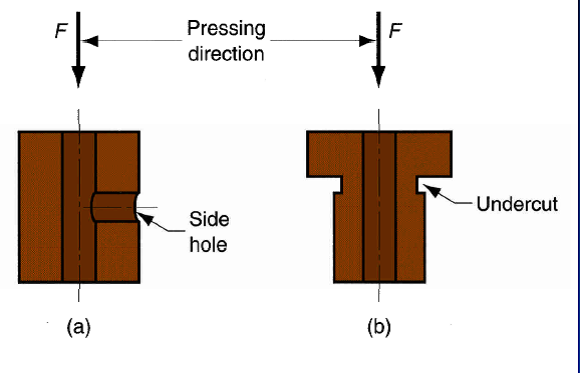

The part geometry must permit ejection from die after pressing. This generally means that part must have vertical or near-vertical sides, although steps are allowed.

Design features such as undercuts and holes on the part sides must be avoided. Vertical undercuts and holes are permissible because they do not interfere with ejection.

Screw threads cannot be fabricated by PM; if required, they must be machined into the part.

Chamfers and corner radii are possible by PM pressing, but problems arise in punch rigidity when angles are too acute.

Wall thickness should be a minimum of 1.5 mm (0.060 in) between holes or a hole and outside wall.

Minimum recommended hole diameter is 1.5 mm (0.060 in).

For more information on P/M bearings follow the links below: