Bronze Liners and Wear Plates for Metal Rolling Mills

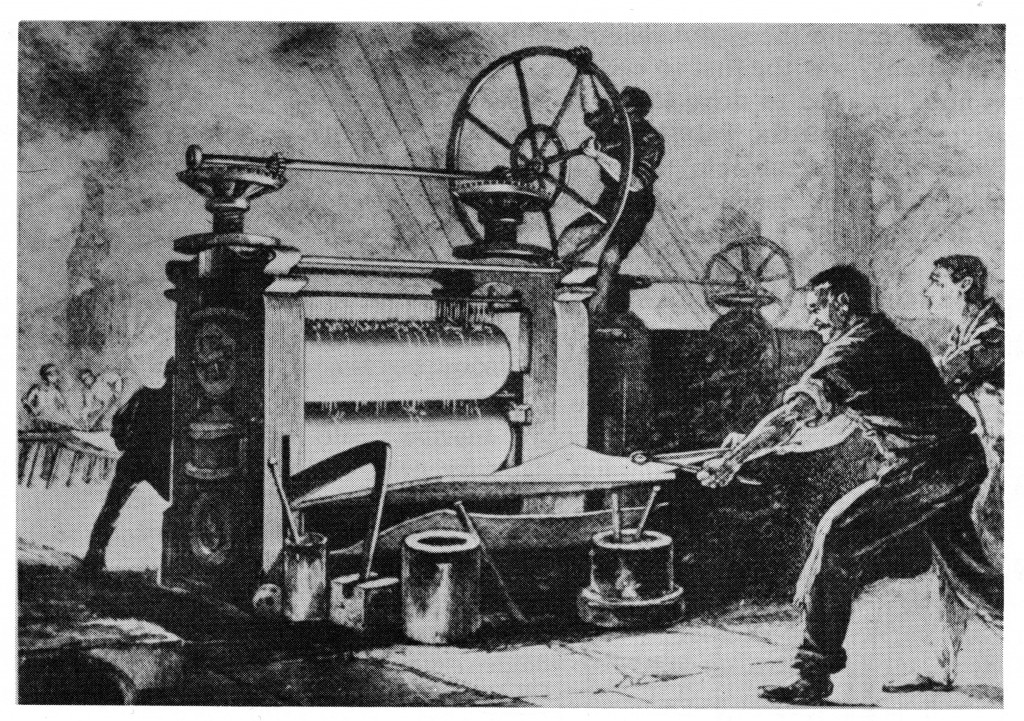

Bronze liners or wear Plates play a critical role in the metal forming process known as rolling. Rolling is the process in which metal stock is passed through one or more pairs of rolls. The material is fed between rollers called working rolls. The gap between the two rolls is less than the thickness of the starting material, which causes it to deform. The decrease in material thickness causes the material to elongate. The concept is similar to the rolling of dough.

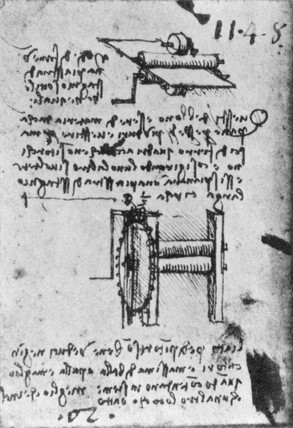

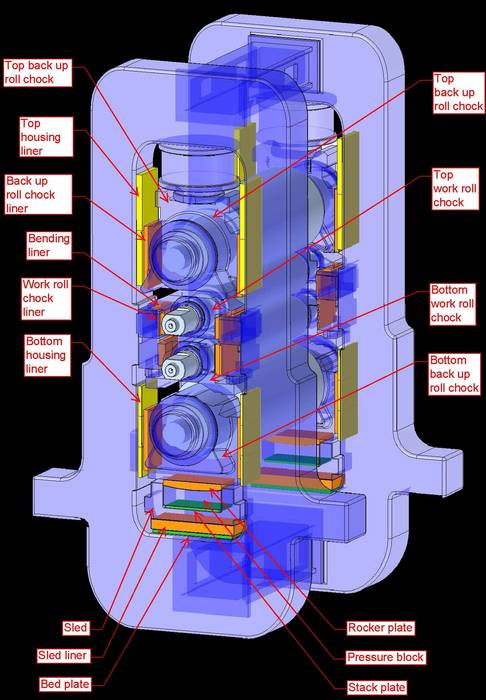

This entire process takes place on machinery called rolling mills. Rolling mills date back hundreds of years, with the invention of the rolling mill being credited to Leonardo Da Vinci. Bronze liners and wear plates are used in multiple locations throughout the rolling mill. They are critical to achieving maximum quality of the product being rolled. For a mill to roll any product to an accurate shape and size, the alignment of the rolls and roll gap must be precisely maintained.

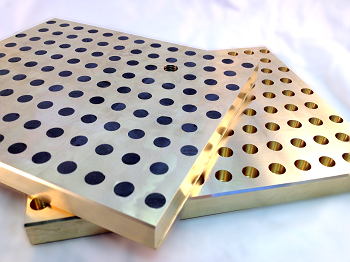

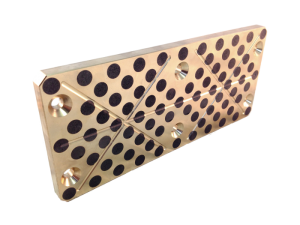

Bronze liners are used on multiple wear surfaces throughout a rolling mill. The ultimate goal of the bronze liners is to assist in keeping the roll center lines at precisely the desired locations. In addition to a high quality end product, use of the proper bronze liners can minimize maintenance costs. Liner systems of bronze alloys can be engineered to maximize liner life. Maintenance costs are reduced when the liner system is engineered so that the less expensive and easier to replace liners wear out and the surfaces of the more expensive and difficult to replace liners do not incur wear.

One of the key points to remember when designing rolling mill liner systems is that the two surfaces in contact with each other have different hardness and good surface finish. Varying the hardness prevents galling and determines which part wears more quickly. An effective way of controlling the hardness variation of the bronze liners is to use different bronze alloys as the base metal of liners in various locations throughout the rolling mill. Two very popular bronze alloys used for rolling mill liners are C93200 SAE 660 Bearing Bronze and C95400 Aluminum Bronze. The C932 bronze can be used in liners that are easier to replace. This alloy is not as hard as the C954 Aluminum Bronze and has excellent wear properties. Liners manufactured from this alloy can be used in locations that are easy to replace, use of the C932 Bearing Bronze Liner can protect the more expensive and critical components. C95400 Aluminum Bronze Liners are harder than the C932 Bronze Liners and can be used in areas that are more difficult to replace and must last longer. C95400 Aluminum Bronze liners have a high resistance to corrosion, and thus can be used in corrosive environments. Corrosion tends to be a problem in hot mills at or below the pass line where the parts are exposed to water and high temperatures. Corrosion can cause pitting and flaking, leading to liner wear. Water and scale at high temperatures cause erosion to the liner surfaces.

An additional option that is often used for these types of liners is the use of solid lubrication plugs. These graphite plugs give the bronze liners the added benefit of self-lubrication. The plug graphite wear liners are ideal for applications with high temperatures that can burn off other common forms of lubrication. As well as liners in locations that are difficult to access for routine maintenance.

As we covered earlier, choosing the liner material based on the mill type and liner location improves the performance of the equipment. The list below describes some of the most common locations in rolling mills that employ the use of a bronze liner.

Housing Liners- Close clearances between the mill housings and the backup roll chocks are maintained by the housing liners, enabling the mill to roll strip to a precise shape and gauge.

Backup Roll Chock Liners- Backup roll outside chock liners protect the chock from wear and allow close clearances between the mill housing and backup roll chocks. This helps to maintain roll alignment and gaps, which both contribute to the ability of the mill to roll strip to a precise shape and gauge.

- The important material consideration for backup roll chock liners is the hardness of the parts they contact. A part with a higher hardness will abrade one of lower hardness. Thus, outside backup roll chock liners should be lower in hardness than the housing liners they contact. Since backup rolls are replaced less frequently than work rolls, backup roll liners are not as accessible.

Work Roll Bearing Box Liners – Work roll bearing box liners protect the work roll bearing box from wear and allow for close clearances between the work roll chock and either the backup roll or the Mae West Block. These close clearances help to maintain roll alignment and the roll gaps and to contribute to the prices strip shape and gauge. Work roll bearing box liners contact the inside leg liners of the backup roll chocks. In mills of a Mae West design, the work roll chocks contact the Mae West block.

- Since work rolls are frequently changed, work roll liners are very accessible. Due to their size, they are inexpensive to replace. For these reasons, work roll liners are manufactured from alloys with slightly lower hardness and wear properties than the liners they contact.

As you can see bronze liners and wear plates play a very important role in multiple locations on today’s metal rolling equipment. Using poorly designed liners or liners that are not compatible with the surfaces they contact can greatly reduce the product quality and increase maintenance expense. Use this article as a starting point for you rolling mill liner design. Explore the links below to learn more about the individual alloys of bronze and their specific properties. Here at National Bronze Mfg. Co. we have been machining bronze liners and wear plates for various steel and other metal mills throughout the world. Our quality products and superior customer service has assisted a number of mills and mill service companies for many years.