What is Naval Brass?

Naval Brass refers to a copper alloy of around 59% Copper 40% Zinc and 1% Tin with a trace amount of Lead. This alloy falls into the subfamily for Brasses known as Alpha Beta or Duplex Brasses. These Alpha Beta Brasses are generally harder and stronger than other non-Alpha Beta Brasses.

As its name implies, Naval Brass was originally developed for sea water service applications. Tin in included in the alloy composition in order to improve the corrosion resistance of Naval Brass. The presence of lead in Naval Brass assists in the machinability of the metal. C464 Naval Brass Rod has a fair machinability with about 35% of Free Machining Brass.

The addition of Tin also gives Naval Brass a high resistance to dezincification. Dezincification is a type of dealloying in which one of the constitutes of an alloy is removed by corrosion. Dezincification was first recognized as a serious problem in brass tubes used for ship condensers around 1920. At the time this problem was referred to as “Condenseritis”. Since then various alloys have been formulated to stop this process, one of which being Naval Brass.

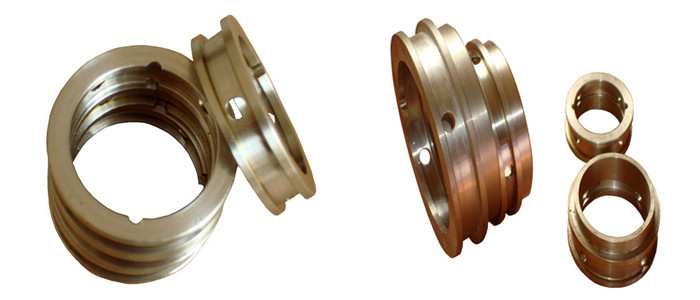

Naval Brass is used extensively in marine hardware applications, but the uses don’t stop there. Its higher tensile strength and resistance to wear make it applicable in bushings and wear strip as well as fastener and valve stem applications.

National Bronze Mfg. supplies C46400 Naval Brass in Round Rod, Plate, and Hex form. Review the below specification chart to determine is C464 Naval Brass is right for your application. Click Here to request a quote for C46400 Naval Brass Today.