C90700 SAE65 Gear Bronze / C907 High Tin Bronze

C90700 SAE65 Gear Bronze / C907 High Tin Bronze

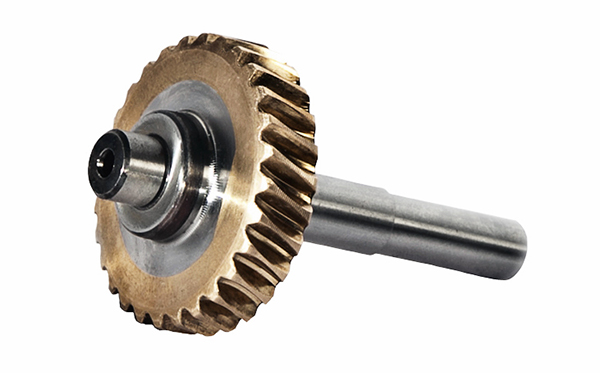

The Bronze Alloy of choice for worm gears is C90700 (SAE65) High Tin Bronze. This has been the predominant bronze alloy for gear manufacturing throughout the 20th century, and continues to prevail today. High Tin Bronze Alloys include those which contain at least 6% tin. The addition of tin to these alloys is designed to strengthen the bronze.

Shapes

Applications

- Gears

- Worm Gears

- Bearings for Heavy Loads

- Gear Boxes

- Speed Reducers

- Valve Bodies

- Worm Wheels

Specifications

CHEMICAL COMPOSITION:

(%max., unless shown as range or min.)

NOTE: Information courtesy of Copper.org

| Cu(1) | Al | Sb | Fe | Pb | Ni(2) | P(3) | Si | S | Sn | Zn | |

| Min./Max. | 88.0-90.0 | .005 | .20 | .15 | .50 | .50 | .30 | .005 | .05 | 10.0-12.0 | .50 |

| Nominal | 89.0 | - | - | - | - | - | - | - | - | 11.0 | - |

MECHANICAL PROPERTIES:

(measured at room temperature, 68 F (20 C)

NOTE: Information courtesy of Copper.org

| Temper | Section Size |

Cold Work |

Typ/ Min |

Temp | Tensile Strength |

Yield Strength (0.5% ext. under load) |

El | Rockwell Hardness |

Brinell Hard. |

Shear Strength |

Fatigue Strength* |

||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| in. | % | F | ksi | ksi | % | B | C | F | 30T | 500 | 3000 | ksi | ksi | ||||||

| mm. | C | MPa | MPa | MPa | MPa | ||||||||||||||

| As Sand Cast | |||||||||||||||||||

| M01 | 0.0 | 0 | TYP | 68 | 44 | 22 | 20 | - | - | - | - | 80 | - | - | 25 | ||||

| 0.0 | 20 | 303 | 152 | 20 | - | - | - | - | 80 | - | - | 172 | |||||||

| M01 | 0.0 | 0 | SMIN | 68 | 35 | 17 | 10 | - | - | - | - | 65 | - | - | - | ||||

| 0.0 | 20 | 241 | 117 | 10 | - | - | - | - | 65 | - | - | - | |||||||

| As Centrifugal Cast | |||||||||||||||||||

| M02 | 0.0 | 0 | TYP | 68 | 55 | 30 | 16 | - | - | - | - | 102 | - | - | - | ||||

| 0.0 | 20 | 379 | 207 | 16 | - | - | - | - | 102 | - | - | - | |||||||

| As Continuous Cast | |||||||||||||||||||

| M07 | 0.0 | 0 | SMIN | 68 | 40 | 25 | 10 | - | - | - | - | - | - | - | - | ||||

| 0.0 | 20 | 276 | 172 | 10 | - | - | - | - | - | - | - | - | |||||||

| As Permanent Mold Cast | |||||||||||||||||||

| M05 | 0.0 | 0 | TYP | 68 | 55 | 30 | 16 | - | - | - | - | 102 | - | - | - | ||||

| 0.0 | 20 | 379 | 207 | 16 | - | - | - | - | 102 | - | - | - | |||||||

| As Centrifugal Cast | |||||||||||||||||||

| M02 | 0.0 | 0 | SMIN | 68 | 50 | 28 | 12 | - | - | - | - | 95 | - | - | - | ||||

| 0.0 | 20 | 345 | 193 | 12 | - | - | - | - | 95 | - | - | - | |||||||

| Product | Specification |

| Centrifugal | ASTM B427 SAE J462, J461 |

| Continuous | ASTM B505 SAE J461, J462 |

| Ingot | ASTM B30 |

| Sand | ASTM B427 SAE J461, J462 |

local:586.791.2000

local:586.791.2000 Email Us Today!

Email Us Today!