C86300 (SAE430B) Manganese Bronze / C863 Manganese Bronze

C86300 Manganese Bronze / C863 Manganese Bronze

SAE 430B bronze can operate at low speeds under heavy loads, but require high shaft hardness and nonabrasive operating conditions. This alloy has excellent mechanical qualities and good corrosion resistance. This alloy is compromised of copper, manganese, aluminum and iron. This combination raises the tensile strength.

Shapes

|

|

|

Cored Bar Stock |

Solid Round Bar Stock |

Plate Stock |

Applications

![]()

- Bushings

- High Strength Machine Parts

- Bridge Pins

- Hydraulic Cylinder Parts

- Heavy Load Bearings

- Valve Stems

- Forming Dies

- Wear Rings

Specifications

CHEMICAL COMPOSITION:

(%max., unless shown as range or min.)

NOTE: Information courtesy of Copper.org

| Cu(1) | Al | Sb | Fe | Pb | Ni(2) | P(3) | Si | S | Sn | Zn | |

| Min./Max. | 84.0-86.0 | .005 | .25 | .30 | 4.0-6.0 | 1.0 | .05 | .005 | .08 | 4.0-6.0 | 4.0-6.0 |

| Nominal | 85.0 | - | - | - | 5.0 | - | - | - | - | 5.0 | 5.0 |

MECHANICAL PROPERTIES:

(measured at room temperature, 68 F (20 C)

NOTE: Information courtesy of Copper.org

| Temper | Section Size |

Cold Work |

Typ/ Min |

Temp | Tensile Strength |

Yield Strength (0.5% ext. under load) |

El | Rockwell Hardness |

Brinell Hard. |

Fatigue Strength* |

|||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| in. | % | F | ksi | ksi | % | B | C | F | 30T | 500 | 3000 | ksi | |||||||

| mm. | C | MPa | MPa | MPa | |||||||||||||||

| As Sand Cast | |||||||||||||||||||

| M01 | 0.0 | 0 | TYP | 68 | 110 | 60 | 30 | - | - | - | - | 60 | - | 11 | |||||

| 0.0 | 20 | 77.3 | 42.2 | 30 | - | - | - | - | 60 | - | 76 | ||||||||

| As Centrifugal Cast | |||||||||||||||||||

| M02 | 0.0 | 0 | SMIN | 68 | 110 | 65 | 20 | - | - | - | - | - | - | - | |||||

| 0.0 | 20 | 207 | 97 | 20 | - | - | - | - | - | - | - | ||||||||

| As Continuous Cast | |||||||||||||||||||

| M07 | 0.0 | 0 | SMIN | 68 | 110 | 65 | 15 | - | - | - | - | - | - | - | |||||

| 0.0 | 20 | 248 | 131 | 15 | - | - | - | - | - | - | - | ||||||||

| As Sand Cast | |||||||||||||||||||

| M01 | 0.0 | 0 | SMIN | 68 | 30 | 14 | 20 | - | - | - | - | - | - | - | |||||

| 0.0 | 20 | 205 | 97 | 20 | - | - | - | - | - | - | - | ||||||||

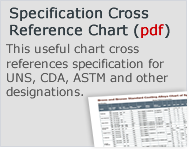

APPLICABLE SPECIFICATIONS:

NOTE: Information courtesy of Copper.org

| Product | Specification |

| Centrifugal | AMS 4855 ASTM B271 SAE J462, J461 |

| Continuous | ASTM B505 SAE J462, J461 |

| Fittings | ASME B16.15, SB62, B16.32, B16.26, B16.23, B16.18 ASTM B62 FEDERAL WW-P-460 |

| Flanges | ASME SB62, B16.24 ASTM B62 |

| Ingot | ASTM B30 |

| Precision | MILITARY MIL-C-11866 |

| Sand | AMS 4855 ASME SB62 ASTM B584, B62 SAE J461, J462 |

| Unions | FEDERAL WW-U-516 |

local:586.791.2000

local:586.791.2000 Email Us Today!

Email Us Today!