C61400 Aluminum Bronze / C614 Aluminum Bronze

C61400 Aluminum Bronze / C614 Aluminum Bronze

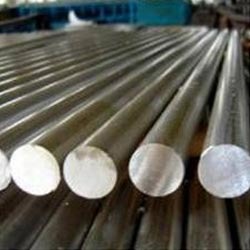

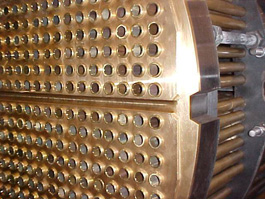

C61400 is a wrought Aluminum Bronze Alloy. C614 has excellent ductiliy properties. It is often used for wearplates where dimensions exceed the limits of rectangular aluminum bronze bar. C61400 is also recomended for corrosive applications. C61400 Plate is resistant to grain boundary stress cracking. This is acheived by a small addition of Tin to the composition. C614 plate is used in fabrications that are either too large to stress relieve or which must be field constructed and welded. In these applications C61400 plate is free from the danger of stress corrosion cracking.

C61400 Plate simplifies field repairs. You can weld readily without any electrical process, without pre heat or post heat, and without hot short cracking.

Shapes

Applications

- Wear Plates

- Structural Units in Process Equipment

- Vessels with High Pressure Requirements

- Heat Exchangers

- Cylinder Mold Tie Rods

- Ball Socket Seats

- Fasteners

Specifications

| Cu(1) | Al | Fe | Pb | Mn | P | Zn | |

| Min./Max. | Rem. | 6.0-8.0 | 1.5-3.5 | .01 | 1.0 | .015 | .20 |

| Nominal | 91.0 | 7.0 | 2.0 | - | - | - | - |

Mechanical Properties (measured at room temperature, 68 F (20 C)

| Temper | Section Size |

Cold Work |

Typ/ Min |

Temp | Tensile Strength |

Yield Strength (0.5% ext. under load) |

El | Rockwell Hardness |

Brinell Hard. |

Shear Strength |

Fatigue Strength* |

||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| in. | % | F | ksi | ksi | % | B | C | F | 30T | 500 | 3000 | ksi | ksi | ||||||

| mm. | C | MPa | MPa | MPa | MPa | ||||||||||||||

| Flat Products | O60 | 1 | 0 | TYP | 68 | 76 | 33 | 45 | 81 | - | - | - | - | - | 40 | 28 | |||

| 25.4 | 20 | 524 | 228 | 45 | 81 | - | - | - | - | - | 276 | 193 | |||||||

| H04 | 0.125 | 0 | TYP | 68 | 89 | 60 | 32 | 87 | - | - | - | - | - | - | - | ||||

| 3.18 | 20 | 614 | 414 | 32 | 87 | - | - | - | - | - | - | - | |||||||

| H04 | 0.5 | 0 | TYP | 68 | 80 | 54 | 38 | 85 | - | - | - | - | - | - | - | ||||

| 12.7 | 20 | 552 | 372 | 38 | 85 | - | - | - | - | - | - | - | |||||||

| Rod | H04 | 1 | 0 | TYP | 68 | 82 | 40 | 35 | 90 | - | - | - | - | - | 45 | - | |||

| 25.4 | 20 | 565 | 276 | 35 | 90 | - | - | - | - | - | 310 | - | |||||||

| H04 | 2 | 0 | TYP | 68 | 80 | 35 | 35 | 88 | - | - | - | - | - | 40 | - | ||||

| 51 | 20 | 552 | 241 | 35 | 88 | - | - | - | - | - | 276 | - | |||||||

| Flat Products | O60 | 0.312 | 0 | TYP | 68 | 80 | 40 | 40 | 83 | - | - | - | - | - | 42 | 26 | |||

| 7.9 | 20 | 552 | 276 | 40 | 83 | - | - | - | - | - | 290 | 179 | |||||||

| O60 | 0.125 | 0 | TYP | 68 | 82 | 45 | 40 | 84 | - | - | - | - | - | 45 | 30 | ||||

| 3.18 | 20 | 565 | 310 | 40 | 84 | - | - | - | - | - | 310 | 207 | |||||||

| Rod | H04 | 0.5 | 0 | TYP | 68 | 85 | 45 | 35 | 91 | - | - | - | - | - | 48 | - | |||

| 12.7 | 20 | 586 | 310 | 35 | 91 | - | - | - | - | - | 331 | - | |||||||

| Flat Products | O60 | 0.5 | 0 | TYP | 68 | 78 | 35 | 42 | 82 | - | - | - | - | - | 40 | 25 | |||

| 12.7 | 20 | 538 | 241 | 42 | 82 | - | - | - | - | - | 276 | 172 | |||||||

| H04 | 1 | 0 | TYP | 68 | 78 | 45 | 40 | 84 | - | - | - | - | - | - | - | ||||

| 25.4 | 20 | 538 | 310 | 40 | 84 | - | - | - | - | - | - | - | |||||||

| H04 | 0.312 | 0 | TYP | 68 | 85 | 58 | 35 | 86 | - | - | - | - | - | - | - | ||||

| 7.9 | 20 | 586 | 400 | 35 | 86 | - | - | - | - | - | - | - | |||||||

![]()

local:586.791.2000

local:586.791.2000 Email Us Today!

Email Us Today!