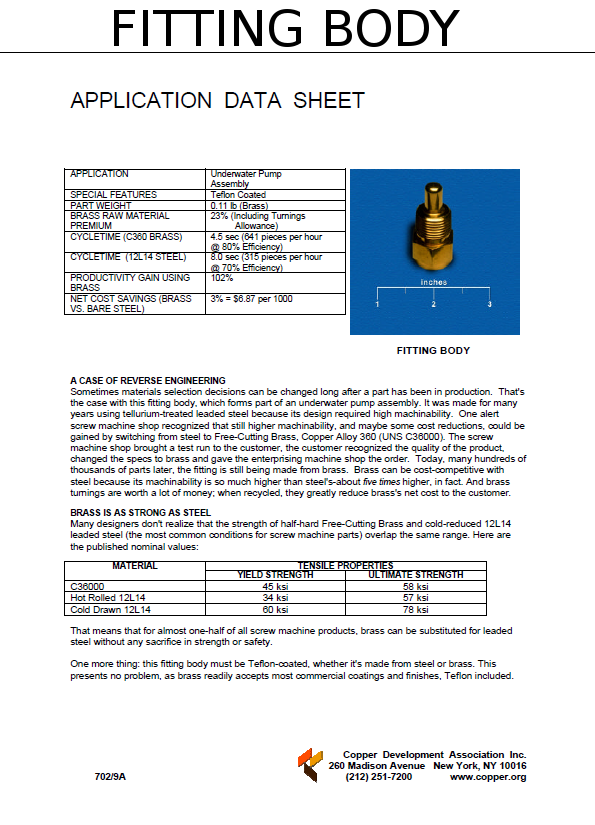

C36000 Free Cutting Brass Bar / C360 Brass / Free Machining Brass

C36000 Free Cutting Brass Bar / C360 Free Machining Brass

C36000 Brass is commonly known as "Free Cutting" or "Free Machining" Brass. With a machinability rating of 100 this material is the standard by which all other metals are measured by. The 2 phase structure of C360 tends to form broken chips instead of continous coils, which interfere with high speed machining. This brass alloy is suited for high speed machining. The lead content adds internal lubrication against the surface of the cutting tool. The high machinability rating of C36000 Free Machining Brass permits full utilization of screw machines speeds and feeds capabilities. C360 has superior machinability, thread rolling and knurling characteristics. In half hard condition, C360 brass can be a substitute for leaded steel in a majority of common screw machine products.

Shapes

|

|

|

Solid Round |

Flat Bar Stock |

Hex Bar Stock |

Applications

- Screw Machine Products

- Valve Components

- Fasteners

- Fittings

- Hardware

- Fluid Connectors

- Automotive Sensor Housings

Specifications

(%max., unless shown as range or min.)

| Cu | Fe | Pb | Zn | |

| Min./Max. | 60.0-63.0 | .35 | 2.5-3.0 | Rem. |

| Nominal | 61.5 | - | 2.7 | 35.4 |

Mechanical Properties (measured at room temperature, 68 F (20 C)

| Temper | Section Size |

Cold Work |

Typ/ Min |

Temp | Tensile Strength |

Yield Strength (0.5% ext. under load) |

El | Rockwell Hardness |

Brinell Hard. |

Shear Strength |

Fatigue Strength* |

||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| in. | % | F | ksi | ksi | % | B | C | F | 30T | 500 | 3000 | ksi | ksi | ||||||

| mm. | C | MPa | MPa | MPa | MPa | ||||||||||||||

| Rod | H04 | 0.375 | 0 | TYP | 68 | - | - | - | 78 | - | - | - | - | - | 34 | - | |||

| 12.7 | 20 | - | - | - | 78 | - | - | - | - | - | 234 | - | |||||||

| H02 | 1.5 | 0 | TYP | 68 | - | - | - | 65 | - | - | - | - | - | - | - | ||||

| 38.1 | 20 | - | - | - | 65 | - | - | - | - | - | - | - | |||||||

| H04 | 0.625 | 0 | SMIN | 68 | 65 | 30 | 6 | - | - | - | - | - | - | - | - | ||||

| 15.9 | 20 | 450 | 205 | 6 | - | - | - | - | - | - | - | - | |||||||

| H02 | 3.0 | 0 | SMIN | 68 | 45 | 15 | 20 | - | - | - | - | - | - | - | - | ||||

| 76.2 | 20 | 310 | 105 | 20 | - | - | - | - | - | - | - | - | |||||||

| O60 | 1.5 | 0 | SMIN | 68 | 44 | 18 | 20 | - | - | - | - | - | - | - | - | ||||

| 38.1 | 20 | 305 | 18 | 20 | - | - | - | - | - | - | - | - | |||||||

| H02 | 0.75 | 0 | MIN | 68 | - | - | - | 70 | - | - | - | - | - | - | - | ||||

| 19.1 | 20 | - | - | - | 70 | - | - | - | - | - | - | - | |||||||

| H02 | <0.50 | 0 | TYP | 68 | - | - | - | 65 | - | - | - | - | - | 32 | 20 | ||||

| 12.7 | 20 | - | - | - | 65 | - | - | - | - | - | 221 | 138 | |||||||

| Bar | H02 | <0.50 | 0 | SMIN | 68 | 50 | 25 | 10 | - | - | - | - | - | - | - | - | |||

| <12.7 | 20 | 345 | 170 | 10 | - | - | - | - | - | - | - | - | |||||||

| O60 | 1.5 | 0 | SMIN | 68 | 40 | 15 | 25 | - | - | - | - | - | - | - | - | ||||

| 38.1 | 20 | 275 | 105 | 25 | - | - | - | - | - | - | - | - | |||||||

| Shapes | H01 | 0.5 | 11 | TYP | 68 | 56 | 45 | 20 | 62 | - | - | - | - | - | 33 | - | |||

| 12.7 | 20 | 386 | 310 | 20 | 62 | - | - | - | - | - | 228 | - | |||||||

| M30 | 0.5 | 0 | TYP | 68 | 49 | 18 | 50 | - | - | 68 | - | - | - | 30 | - | ||||

| 12.7 | 20 | 338 | 124 | 50 | - | - | 68 | - | - | - | 207 | - | |||||||

| Rod | H02 | 1.5 | 0 | SMIN | 68 | 50 | 20 | 15 | - | - | - | - | - | - | - | - | |||

| 38.1 | 20 | 345 | 140 | 15 | - | - | - | - | - | - | - | - | |||||||

| O60 | <1 | 0 | SMIN | 68 | 48 | 20 | 15 | - | - | - | - | - | - | - | - | ||||

| <25.4 | 20 | 330 | 124 | 15 | - | - | - | - | - | - | - | - | |||||||

| Bar | H02 | 1.5 | 0 | TYP | 68 | - | - | - | 60 | - | - | - | - | - | - | - | |||

| 38.1 | 20 | - | - | - | 60 | - | - | - | - | - | - | - | |||||||

| H02 | <0.50 | 0 | TYP | 68 | - | - | - | 65 | - | - | - | - | - | - | - | ||||

| <12.7 | 20 | - | - | - | 65 | - | - | - | - | - | - | - | |||||||

| Rod | H02 | 4.5 | 0 | SMIN | 68 | 40 | 15 | 20 | 25 | - | - | - | - | - | - | - | |||

| 114.3 | 20 | 275 | 105 | 20 | 25 | - | - | - | - | - | - | - | |||||||

| H04 | 0.25 | 0 | TYP | 68 | - | - | - | 80 | - | - | - | - | - | 38 | - | ||||

| 6.35 | 20 | - | - | - | 80 | - | - | - | - | - | 262 | - | |||||||

| Flat Products | H02 | 0.25 | 11 | TYP | 68 | 56 | 45 | 20 | 62 | - | - | - | - | - | 33 | - | |||

| 4.76 | 20 | 386 | 310 | 20 | 62 | - | - | - | - | - | 228 | - | |||||||

| Rod | H04 | 0.375 | 0 | SMIN | 68 | 70 | 35 | 4 | - | - | - | - | - | - | - | - | |||

| 12.7 | 20 | 480 | 240 | 4 | - | - | - | - | - | - | - | - | |||||||

| H02 | 0.75 | 0 | SMIN | 68 | 55 | 25 | 10 | - | - | - | - | - | - | 34 | - | ||||

| 19.1 | 20 | 380 | 170 | 10 | - | - | - | - | - | - | 234 | - | |||||||

| H02 | 3.0 | 0 | TYP | 68 | - | - | - | 55 | - | - | - | - | - | - | - | ||||

| 76.2 | 20 | - | - | - | 55 | - | - | - | - | - | - | - | |||||||

| Bar | O60 | <1 | 0 | SMIN | 68 | 44 | 18 | 20 | - | - | - | - | - | - | - | - | |||

| <25.4 | 20 | 305 | 125 | 20 | - | - | - | - | - | - | - | - | |||||||

| Rod | O60 | <1 | 0 | TYP | 68 | - | - | - | 28 | - | - | - | - | - | 30 | - | |||

| <25.4 | 20 | - | - | - | 28 | - | - | - | - | - | 207 | - | |||||||

| H04 | 0.25 | 0 | SMIN | 68 | 80 | 45 | - | - | - | - | - | - | - | - | - | ||||

| 6.35 | 20 | 550 | 310 | - | - | - | - | - | - | - | - | - | |||||||

| O60 | 2.5 | 0 | SMIN | 68 | 40 | 15 | 25 | - | - | - | - | - | - | - | - | ||||

| 63.5 | 20 | 40 | 15 | 25 | - | - | - | - | - | - | - | - | |||||||

| H02 | <0.50 | 0 | TYP | 68 | 57 | 25 | 7 | - | - | - | - | - | - | - | - | ||||

| 12.7 | 20 | 395 | 170 | 7 | - | - | - | - | - | - | - | - | |||||||

| Bar | H02 | 3 | 0 | SMIN | 68 | 40 | 15 | 20 | - | - | - | - | - | - | - | - | |||

| 76.2 | 20 | 275 | 105 | 20 | - | - | - | - | - | - | - | - | |||||||

| H02 | 1.5 | 0 | SMIN | 68 | 45 | 17 | 15 | - | - | - | - | - | - | - | - | ||||

| 38.1 | 20 | 310 | 115 | 15 | - | - | - | - | - | - | - | - | |||||||

| O60 | 1.5 | 0 | TYP | 68 | - | - | - | 22 | - | - | - | - | - | - | - | ||||

| 38.1 | 20 | - | - | - | 22 | - | - | - | - | - | - | - | |||||||

local:586.791.2000

local:586.791.2000 Email Us Today!

Email Us Today!