C18200 Chromium Copper Bar / C182 Class II Copper

C18200 Chromium Copper / C182 Class II

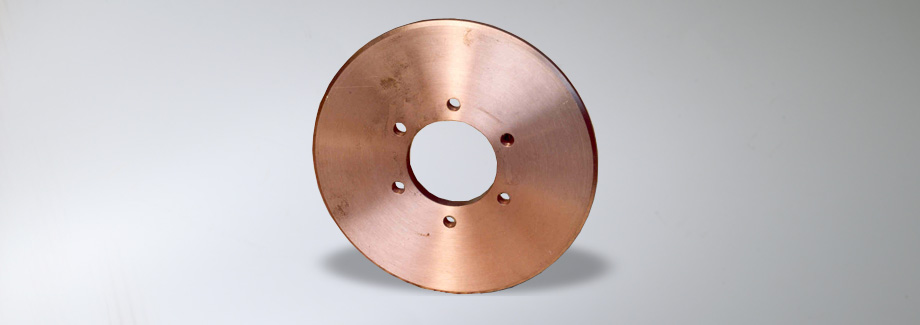

C18200 Class II Chromium Copper is the primary copper alloy used for resistance spot and seam welding. C182 is a high conductivity copper alloy that obtains optimum properties from both heat treatment and cold working. C18200 offers resistance to softening at eleveated temperatures along with good stregnth and hardness. In addition to resistance welding applications C182 is used for numerous electrical applications where resistance to deformation at high temperature is required. The RWMA designation is Class II.

Shapes

Applications

- Resitance Welding Machine Electrodes

- Seam Welding Wheels

- Electrical Switch Gear

- Electrode Holder Jaws

- Molds

- Spot Welding Tips

- Heat Exchangers

Specifications

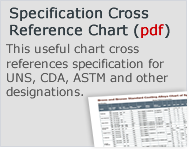

(%max., unless shown as range or min.)

| Cu(1) | Cr | Fe | Pb | Si | |

| Min./Max. | Rem. | .6-1.2 | .10 | .05 | .10 |

| Nominal | 99.1 | .9 | - | - | - |

Mechanical Properties (measured at room temperature, 68 F (20 C)

| Temper | Section Size |

Cold Work |

Typ/ Min |

Temp | Tensile Strength |

Yield Strength (0.5% ext. under load) |

El | Rockwell Hardness |

Brinell Hard. |

Shear Strength |

Fatigue Strength* |

||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| in. | % | F | ksi | ksi | % | B | C | F | 30T | 500 | 3000 | ksi | ksi | ||||||

| mm. | C | MPa | MPa | MPa | MPa | ||||||||||||||

| Tube | TL03 | 0.212 | 76 | TYP | 68 | 69 | 63 | 26 | 84 | - | - | - | - | - | - | - | |||

| 5.4 | 20 | 476 | 434 | 26 | 84 | - | - | - | - | - | - | - | |||||||

| Flat Products | TF00 | 0.04 | 0 | TYP | 68 | 51 | 36 | 22 | 59 | - | - | - | - | - | - | - | |||

| 1 | 20 | 352 | 248 | 22 | 59 | - | - | - | - | - | - | - | |||||||

| TB00 | 0.04 | 0 | TYP | 68 | 34 | 19 | 40 | 16 | - | - | - | - | - | - | - | ||||

| 1 | 20 | 234 | 131 | 40 | 16 | - | - | - | - | - | - | - | |||||||

| Rod | TH04 | 0.5 | 60 | TYP | 68 | 77 | 65 | 16 | 82 | - | - | - | - | - | - | - | |||

| 12.7 | 20 | 531 | 448 | 16 | 82 | - | - | - | - | - | - | - | |||||||

| TB00 | 0.5 | 0 | TYP | 68 | 45 | 14 | 40 | - | - | - | - | - | - | - | - | ||||

| 12.7 | 20 | 310 | 97 | 40 | - | - | - | - | - | - | - | - | |||||||

| TF00 | 2 | 0 | TYP | 68 | 70 | 65 | 18 | 75 | - | - | - | - | - | - | - | ||||

| 51 | 20 | 483 | 448 | 18 | 75 | - | - | - | - | - | - | - | |||||||

| TF00 | 0.5 | 0 | TYP | 68 | 70 | 55 | 21 | 70 | - | - | - | - | - | - | - | ||||

| 12.7 | 20 | 483 | 379 | 21 | 70 | - | - | - | - | - | - | - | |||||||

| TD10 | 0.156 | 91 | TYP | 68 | 74 | 73 | 5 | - | - | - | - | - | - | - | - | ||||

| 3.96 | 20 | 510 | 503 | 5 | - | - | - | - | - | - | - | - | |||||||

| Tube | TD04 | 0.212 | 76 | TYP | 68 | 59 | 57 | 21 | 67 | - | - | - | - | - | - | - | |||

| 5.4 | 20 | 407 | 393 | 21 | 67 | - | - | - | - | - | - | - | |||||||

| Rod | TF00 | 1 | 0 | TYP | 68 | 72 | 65 | 18 | 80 | - | - | - | - | - | - | - | |||

| 25.4 | 20 | 496 | 448 | 18 | 80 | - | - | - | - | - | - | - | |||||||

| TF00 | 4 | 0 | TYP | 68 | 55 | 43 | 25 | 68 | - | - | - | - | - | - | - | ||||

| 102 | 20 | 379 | 296 | 25 | 68 | - | - | - | - | - | - | - | |||||||

| Flat Products | TD00 | 0.04 | 50 | TYP | 68 | 53 | 51 | 6 | 66 | - | - | - | - | - | - | - | |||

| 1 | 20 | 365 | 352 | 6 | 66 | - | - | - | - | - | - | - | |||||||

| Tube | O61 | 0.094 | 0 | TYP | 68 | 40 | 15 | 50 | - | - | 59 | - | - | - | - | - | |||

| 2.4 | 20 | 276 | 103 | 50 | - | - | 59 | - | - | - | - | - | |||||||

| Flat Products | TH01 | 0.04 | 50 | TYP | 68 | 67 | 59 | 14 | 79 | - | - | - | - | - | - | - | |||

| 1 | 20 | 462 | 407 | 14 | 79 | - | - | - | - | - | - | - | |||||||

| Rod | TD04 | 0.5 | 60 | TYP | 68 | 57 | 56 | 11 | 65 | - | - | - | - | - | - | - | |||

| 12.7 | 20 | 393 | 386 | 11 | 65 | - | - | - | - | - | - | - | |||||||

| TH10 | 0.156 | 90 | TYP | 68 | 86 | 77 | 14 | - | - | - | - | - | - | - | - | ||||

| 3.96 | 20 | 593 | 531 | 14 | - | - | - | - | - | - | - | - | |||||||

| TF00 | 3 | 0 | TYP | 68 | 65 | 55 | 18 | 70 | - | - | - | - | - | - | - | ||||

| 76 | 20 | 448 | 379 | 18 | 70 | - | - | - | - | - | - | - | |||||||

| Plate | TF00 | 3 | 0 | TYP | 68 | 56 | 40 | 30 | 68 | - | - | - | - | - | - | - | |||

| 76 | 20 | 386 | 276 | 30 | 68 | - | - | - | - | - | - | - | |||||||

| TF00 | 2 | 0 | TYP | 68 | 58 | 42 | 25 | 70 | - | - | - | - | - | - | - | ||||

| 51 | 20 | 400 | 290 | 25 | 70 | - | - | - | - | - | - | - | |||||||

local:586.791.2000

local:586.791.2000 Email Us Today!

Email Us Today!