How Technology is changing the “Story” of US Manufacturing

“Without continual growth and progress, such words as improvement, achievement,

and success have no meaning.”

Benjamin Franklin

Recently I had the opportunity to attend the 2014 CBSA (Copper and Brass Service Center Association) Service Center Training Event at Mueller Brass Company in Port Huron, MI. The CBSA training events are great educational opportunities offered exclusively to CBSA service center members. Continuous education of the members is one of the top priorities at CBSA. One of the learning opportunities offered by CBSA are these joint events put on by the association and hosting mill. These visits are a full-day session for the service center member employees, with the highlight of the day

being a guided plant tour that allows service center employees to see the products they sell being manufactured. This first-hand experience increases the employee’s product knowledge which, in turn, helps them better perform their job. Accompanying the plant tours are informational presentations ranging from technical knowledge to industry trend reports. All of these presentations are given by the experienced employees of the hosting mill. In the end, it’s a win/win situation for the attending service center personel and the mill. This win/win situation is one of the many benefits of being a CBSA member.

Last year CBSA held its innagural training event at Revere Copper Products, Inc. in Rome, NY for a highly informative day of all things copper. A review of that visit can be found here:

https://www.nationalbronze.com/News/revere-from-midnight-runs-to-continuous-improvement/

This year highlighted the various brass alloys in production at Mueller Brass Company. I find that each training event gives you more than just a thorough understanding of the mill’s product line, you also hear the company’s unique story. I believe that beneath the products a company manufactures is an underlying story that brought them to where they are today and where they will go in the future. This story is much more than a marketing message or mission statement. It is a story that can be told by every employee that works hard day to day to make the company a success.

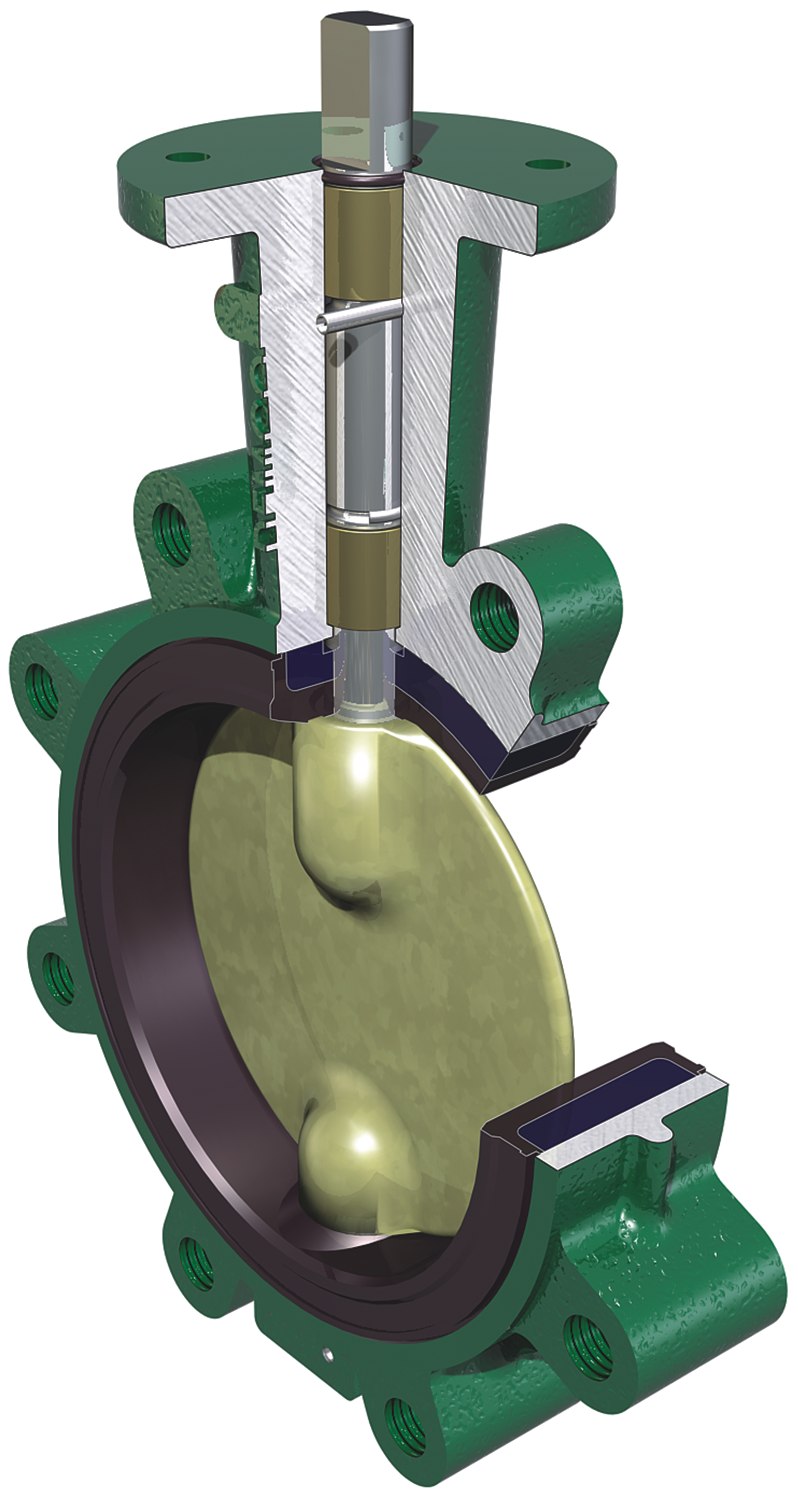

Mueller Industries story is very similar to many other established US manufacturers. Founded in 1917 Mueller thrived through the Industrial Revolution, some say that Mueller Brass is what built the city of Port Huron. In the past the company employed thousands of local residents in the small town. The company even had their own grocery store and gas station to service their employees due to the very small commercial resources of Port Huron. The company supplied US Armed Forces throughout World War II with the production of essential components for war. After the war ended, growth in US demand for durable goods grew the companies’ production of other various components.

Mueller shares a similar story to many manufacturers throughout the 70’s and 80’s. Experiencing tremendous growth during those times follow by decades of decline throughout the 90’s and early 2000’s. The Brass Industry as a whole has been hit with blow after blow from a number of sources over the last decade or so. Beginning with the acceptance of China into the WTO to the crash of the housing market and more recently the passing of the lead free act of 2014. You can graph the amount of US brass production over the years and clearly see the correlation with these events. Since the early 2000’s the amount of imported brass has skyrocketed, reducing the US production drastically. Many US Brass Mills have gone out of business leaving only a few left in the country.

Mueller doesn’t intend to repeat the path of the fallen companies. They are working hard to remain competitive and profitable while facing increasing regulation and foreign competition. The way they are changing their story is through the use of modern technology. Mueller has invested a large amount into modernizing much of their equipment to incorporate state of the art manufacturing technologies. This modernization is a response to the changing market place and needs of their customers. As well as the customer’s needs for smaller lot requirements, many processes have to be changed to remain efficient. Mueller realizes that following the ways of the past are no longer good enough.

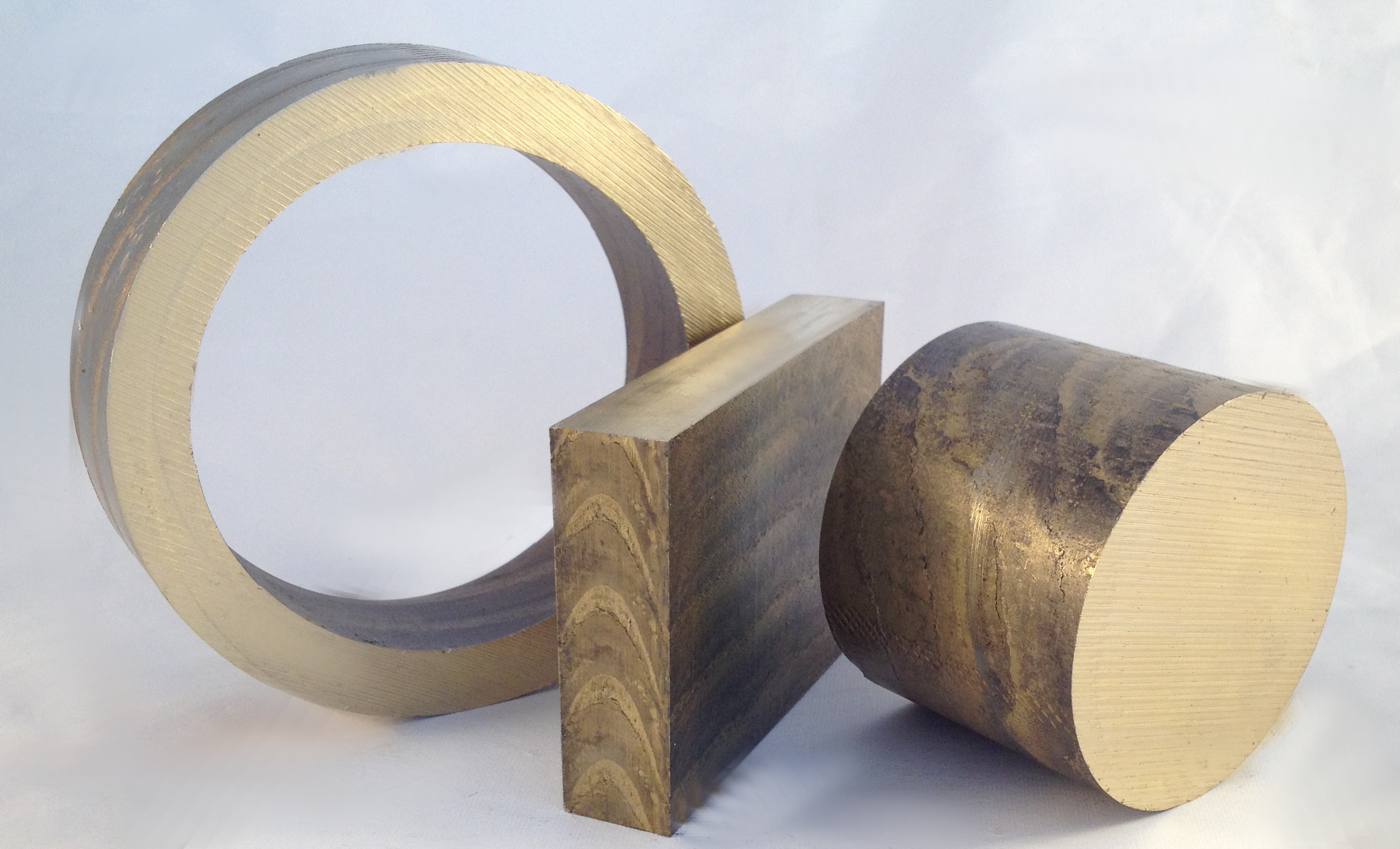

With machining technology advancing in both speed and precision, machine shops of today and tomorrow require the highest of quality bar stock. Mueller has taken a proactive approach to quality instead of waiting for a customer complaint and then correcting the problem. In order to improve their product they needed to understand “how good is good” and “what level of quality” does a customer need. The answer to this question seemed to be that the customer actually values consistency rather than perfection. If a customer knows what they are going to get every time then they can program their machines to accommodate this. To ensure this consistency Mueller has incorporated a large investment in straightening and detection equipment. This equipment incorporates measurement tools to ensure the customer receives what they are promised. All of this equipment is interconnected and tracks important analytical information. This data is used to help Mueller better understand what’s happening before a defective product gets to the customer. By using this analytical approach to proactive quality, Mueller can guarantee the consistency their product every time. They believe that this type of consistent product is what the customer of tomorrow will be looking for. By investing in the necessary equipment today, they ensure a different narrative of their story over the next 20-30 years.

In order to compete in the global environment of the future, US manufactures have to produce the best product as efficiently as possible. This can be achieved with the use of modern high speed precision CNC technology, but can only be done by starting with the proper bar stock. Mueller intends on being the trusted source of this brass bar stock for many years to come. The key to ensuring the resurgence of US manufacturing is combining time proven products with the latest in manufacturing technology. Then using this technology to capture important data that can be analyzed and used to improve. This approach to continuous improvement through technology and big data can give US manufactures the upper hand on competition.

Continuous improvement doesn’t stop at the machinery, it extends to all aspects of a company. Including the knowledge of a trained staff of employees. CBSA is doing their part to increase this knowledge through educational mill visits and other learning opportunities. A membership with CBSA more than just another trade organization, it’s an investment in your company’s future.

Here at National Bronze Mfg. we share many of the same values as Mueller Industries as well as distribute brass alloys. To learn more about the main brass alloy manufactured at Mueller Industries follow the links below:

C36000 Free Machining Brass Product Page

C360 Free Machining Brass for Lower Screw Machine Product Cost

C36000 Free Machining Brass for Automatic Screw Machine Products

Another great article..

Michael, very nice article on your visit to Mueller Brass.